|

|

Firing Andrew´s

kiln

SideStoke

home

| Andrew

home | Kiln

home

|

|

Carol

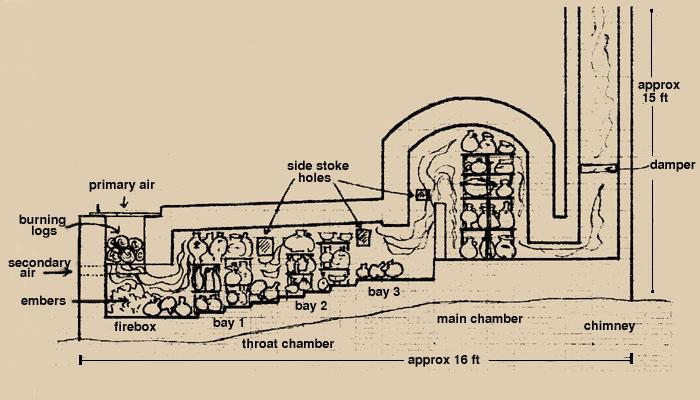

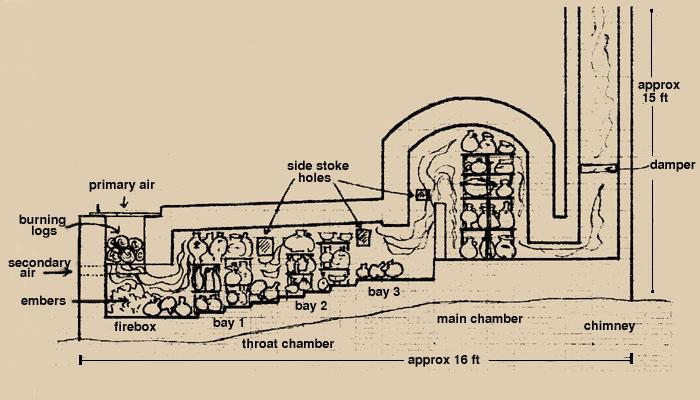

looked at the photos of Andrew´s kiln and wanted to know how

it was fired, so I emailed some questions to him, using the photo

at right for reference. His reply referred to a further diagram

which is reproduced below, along with the questions and his

answers.

|

|

Andrew:

I have attached a cross-section of my kiln which may be of some use

to look at in conjunction with your photo. I have since altered the

floor of the throat to make the steps two bricks long instead of one.

It was too hard to pack with all those little steps. The illustrated

pack is denser than anything I can actually achieve. I now use only

one bung of shelves in the first bay. More space was needed there for

flame expansion and the top front was always a cold spot. The diagram

shows the sidestoking ports, corresponding to 3, 5 and 6 on your

photo, but does not show the mouseholes. There are three, one at the

front of the firebox and one on each side of it, at the level of the

floor. There's another one on each side of behind (in front of?) the

bagwall at position 7.

Do you keep the main

firebox going throughout?

Yes, I do, even if it is only

ticking over. I think of it as an old V8 burbling away with lots of

deep down reserve power. The sidestoking ports can give a quick burst

but have insufficient "grate area" or regulated air supply

(see below) to keep the kiln going on their own. They may do so in a

no-bulli-gama (1) but not when

there is a whole chamber tacked on the end.

When

do you start sidestoking?

No hard and

fast rule for this. There are two considerations: moving thefire

along the kiln to narrow the temperature difference between front

andback; and getting enough reduction at the end of the throat and in

thechamber. The first bay of the throat can be at 1100 or even 1200

before cone06 starts moving in the second bay, while the chamber may

only be 500 or 600. I would probably begin by stoking at 3 at this

stage to try to drop 06 in the second bay in a reducing atmosphere. I

might stoke a bit at 5 aswell, depending on how I feel about the

overall state of the kiln.I used to think it was better to start

sidestoking early, before the first bay got too hot in case I ended

up overfiring it. I thought there would be some virtue in trying to

get the kiln even, before top temperature, and then bring it all up

together. I now think that's probably impossible and even though cone

12 is flat at the front it never gets any hotter and [the clays I

use] can withstand long times at high temperatures, the longer the

better actually.

Once started do you

sidestoke all the throat ports all the time ?

More

or less, although I usually concentrate on one set at a time

according to where I think the heat is needed. This also gives the

other one a chance to burn down since they can get quite full.

Do

you stoke the main chamber directly?

Yes,

eventually I always end up stoking at 6 because I don't think the

chamber is ever going to make it. There's a big difference in the

effect of stoking right behind the bagwall at 6 compared to 5.

Sometimes I may stoke in a wave: 3 then 5 then 6 and back to 3 again

to pull the fire through. It's a long way for the flame to travel

from the firebox to the other end of the kiln without some help along

the way. Yet it's surprising how just a tickle of a sidestoke can

result in a very quick rise and an impressive flame at the top of the

chimney. I would like to try a firing with no sidestoking to see if

it could be done and how long it would take. I suspect it would be a

struggle and the results might be a bit bland but it would be much

less work (splitting as well as stoking) even if the firing took

longer.

The bricks near the numbers

[on the photo]seem to be removable. What

are they all for?

Of the numbers I

have not already identified, 1 and 4 are spyhole bricks and 2 is

where a thermocouple goes in.

Are there any

ports on the other side of the kiln? Do you have any air intakes and

grates below the sidestoke ports as does Sandra Lockwood?

There

are stoking ports in exactly the same positions on the other side of

the kiln as well as a couple more spyholes. Grates and air intakes

would probably improve their performance markedly. They are pretty

inefficient as they are and not all that easy to use.

What

do you do with the damper, and why? It seems to me that if you can

get this kiln to fire reasonably evenly then we should have been able

to get our old

salt kiln to fire more

evenly than we ever did. We never knew what to do with the damper.

I

have to admit that often I am puzzled too. There is a school of

thought that says you should be able to fire with the damper wide

open, using only the air controls at the front of the kiln but I

haven't been able to do it. This kiln can pull a lot of air. The

chimney is one and a half bricks square internally and there is all

that horizontal draught as well as vertical. I don't think the

firebox is big enough to keep up with the draught and it's all too

easy to pull excess cold air through and lose temperature. Observing

the behaviour of the fire at start of the firing (fire on the firebox

floor) is instructive. If the damper is open the fire is erratic,

flaring up and dying back quickly with consequent cycles of soaring

and plummeting temperature, impossible to stabilise. This occurs even

if the stokehole is virtually closed. It is much more manageable with

the damper set at a bit less than half from the start and it will

rarely exceed this at any stage of the firing. In fact it seems to

need closing to 20% or 30% for reduction or even less to get decent

back pressure (2) from the

spyholes in the chamber.

It's easy to succumb to worry that you're

not getting anywhere and to keep fiddling with the damper with an eye

on the digital pyrometer. These quick reacting pyrometers have

developed in tandem with lightweight kilns. There's a lot of inertia

in a brick kiln and you just have to be patient and watch the flame.

A nice fat, lazy flame takes time, not big draughts of cold air. If

I'm honest I must say that I don't really know what I'm doing a lot

of the time. There are a lot of variables, not least the fuel. I'm

still learning the kiln. I've only fired it ten times and with

different people, including Bob Connery and Colin Drake, who have all

had their ideas too. There are lots of ways to fire it. Once I fired

to cone 12 in the first bay, cone 10 in the second and a load of

planters to between cones 03 and 2 in the chamber with no attempt

(and no necessity) to even out the temperature.

How

even is the temperature in the main chamber, at best, when you

finally decide to go to bed?

Looking

back over the logs I see that the cones have been pretty even over

the last four or five firings, at least cone 10 consistently on the

bottom with cone 12 moving higher up. Sometimes cone 12 is nearly

half down on the bottom too. As for the pots themselves, they can be

a little cool down near the exit flues and perhaps all the way down

the back wall. But if there's a good soak it's not too bad.

(1)

The term no-bull-i-gama

was used by Steve Harrison as the name for a kiln of his

which is essentially the same as Andrew´s kiln with the chamber

removed and with a horizontal throat.

(2)

Back pressure refers to the

situation where flames tend to come out of the spyhole when the

spyhole brick is removed.

SideStoke

home |

Andrew

home | Kiln

home

![]()