|

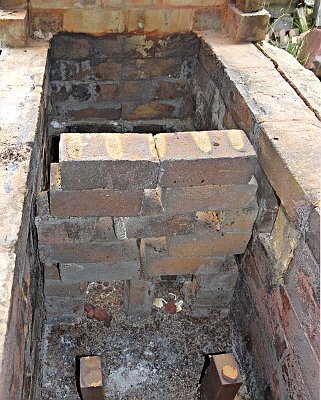

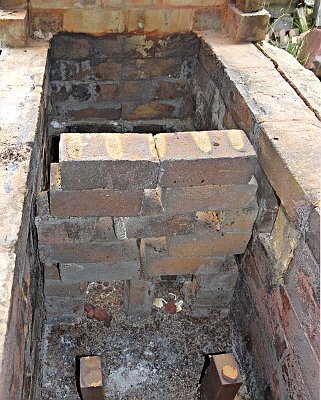

The internal wall was an unintended variation. Because of the limited

time available for the firing it was decided to pack only bisqued pots,

and since Zoe and Dave do not bisque their pots they had none available

for the firing, except refires which had been left out in the rain and

were deemed likely to explode. The wall was built to separate the

refires from the rest of the kiln, and we rather pretentiously called

the separated area a sutema

|

|

|

The

firing was very much like our firings at Eungella, except that the wood

was much drier than it ever gets at home. The back of the kiln

showed its usual reluctance to heat up as much as the area behind the

firebox, and as usual was difficult to reduce. Because of the

absence of larger pots to block the flames at the top of the stack so

as to force them down the flames tended to motor along near the roof of

the chamber until forced down by the sutema wall. Continuous side

stoking through 2 ports relieved both the heat and reduction problem to

some extent. The sidestoking started at the first port when the

temperature behind the firebox was about 1000 C, and

at the second port when the front temperature reached

approximately 1130 C .The lengths and thickness

of the available sidestoking wood encouraged us to do quite a lot of

flamethrower stoking, which under some circumstances can yield short

term temperature rises but on the whole seemed no more effective than

ordinary stoking with shorter pieces of wood. Only towards the end of

the up cycle, when stoking temporarily ceased at the main firebox, and

flame throwers of thin, dry acacia sticks were used, did the

temperature at the back rise quickly. If we use

the sutema wall again we will move it to the firebox side of the second

side stoking port to see if side stoking in the sutema chamber makes

any difference.

|

|

Left: Arthur Rosser introducing bulrushes into the firebox for the

reduced cooling phase of the firing. An oxy probe was used to test that

reduction was maintained, but was not really necessary. About one

fertilizer bag of bulrushes was used.

|

Reduced cooling with

bulrushes as the reducing agent was uneventful, and of course quite

quick, taking only 53 minutes to lower the temperature from

1030 C to 880C according to the pyrometer in the oxy probe (located

about 65cm behind the firebox). Slightly lower

numbers were reported from the probes located closer to the exit flues.

All the numbers have to be regarded as approximate.

Slow oxidised cooling

below 900C was assisted by a gas burner, and the gas supply- burner

arrangement was untested prior to the firing. There did not seem to be

enough pressure to hold the kiln above 800 for the desired 4 hours, and

we had no way to increase the pressure. The temperature drifted

down to a lower temperature than we had planned, to a reported 770 C, before we sealed the kiln.

The temperature distribution

was not what we would have asked for, being very hot at the top of the

first bung (cone 13) and about cone 10 at the second

bung. The third bung was behind the sutema wall, and although the

pyrometers were moderately optimistic about the final temperature there

the well protected cones reported less than cone 9. We regard

cones 10-12 as acceptable and cone 13 as unnecessarily hot. If we use

the sutema wall again we will move it to the firebox side of the second

si |

Some of the work from the firing

Some of the work from the firing

|

Results

On the clay body we use at Eungella the

pots looked very much like the pots fired at Eungella: good red

flashing on bare body where the ash effects were minimal, dark brown or

black (rather than the undesirable mid brown) at the next thickness of

ashing, and greenish glaze where the ash effect was greatest. "Red

shino" liner glaze - really a shino recipe using a proportion of iron

bearing clay - was excellent, with a lustrous surface effect in most

places. Shells used as wads produced good comet effects, and our high

iron dark wad clay behaved normally. Despite different woods and

different reducing medium, which could easily have resulted in very

different effects, the general resemblance to our usual work was

unmistakable. We are more than ever convinced that the reduced cooling

regime used is useful and transferable to different fuels.

Other clay bodies produced a wide range of results, many of them very attactive.

|

|

Platter ruined by snotters

Many

of the shelves used in the kiln had been purchased in used condition

and precisely what they had been used for was not known. Usually this

caused no trouble but one large silicon carbide shelf was placed across

the top of the kiln just behind the firebox, and the temperature

reached cone 13 at that position. The result was a liberal supply of

snotters, probably because the binder for the silicon carbide crystals

in the shelf had been affected by salt glazing. The platter shown was

fired on edge, and the snotters disrupted the intended comet mark

design.

|

| More images of fired pots |